The column is a vertical structural member that transmits the load from the ceiling/roof slab and beam, including its self-weight to the foundation.

Column formwork is designed with a leakproof, smooth inside surface and contains the cement, the sand ratio (1:2) of the poured concrete is maintained in column casting. Square columns, and rectangular columns, circular columns are constructed and steel formwork can be used. Because steel formwork is non-absorbent, less in volume, more strength, easy to use, smooth-finished surface, no shrinkage of formwork occurs, and it can be used many times. Generally, formwork height is maintained at 4’ (feet) because concrete casting in columns is done in 3 or 4 lifts to avoid concrete segregation. Cement grout is used to make a smooth joint, between newly poured concrete and old concrete. Verticality check of column formwork should be done before and after the concrete casting.

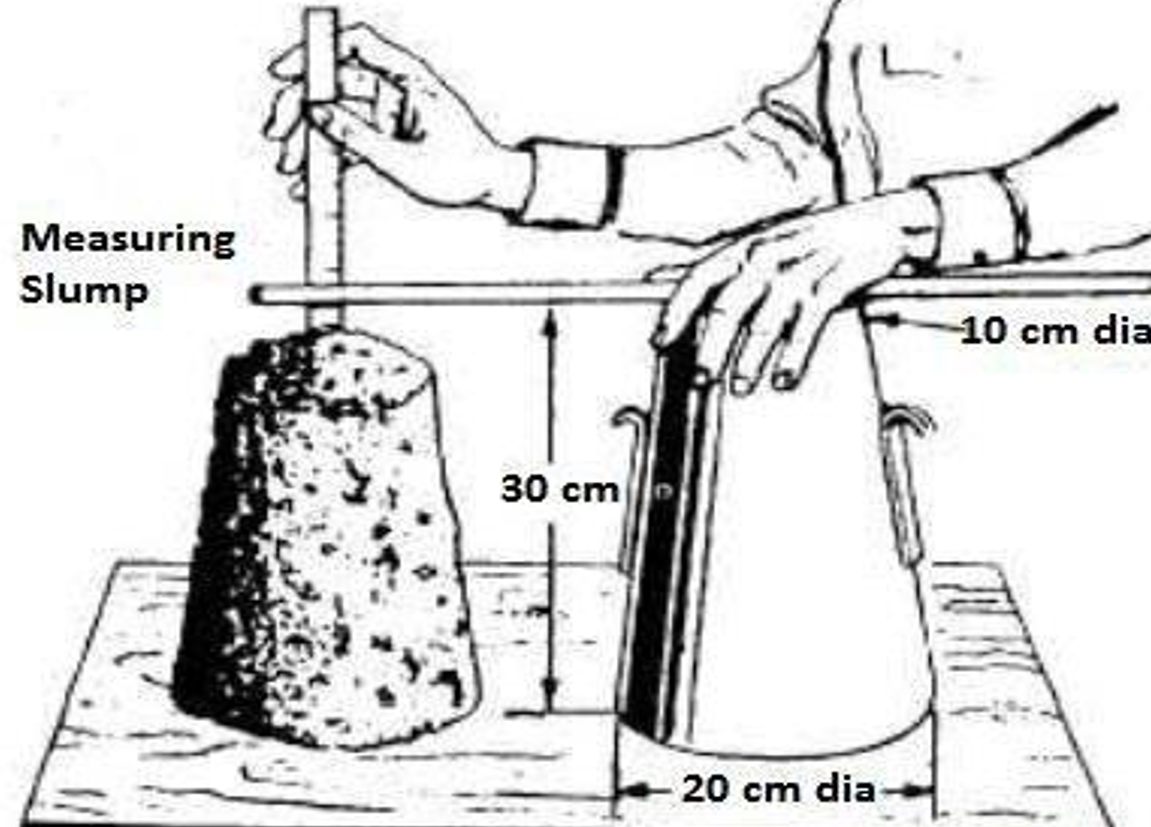

Verticality check of column formwork

Column formwork is supported by inclined jacks, at each face of the column. Then, the verticality check of the column formwork is done by using a plumb-bob. The Plumb-bob line was measured at the top and bottom along the external surface of the steel formwork. Then checked at a particular distance from the top of the formwork. If any deviations were found in the measurement the formwork would be adjusted by adjusting jacks in that direction if the plumb-bob level was correct at 2 adjacent sides of the column formwork. It could be taken the column was vertical.

After the verticality check of column formwork concrete casting was done. And again the verticality check of column formwork was done after the vibrator operation.