Generally plastering is done to conceal the defective workmanship and to protect the external surfaces against the penetration of rainwater, termite, and other atmospheric agencies. Plastering gives a good appearance, smooth surface, and protection to the building’s structural parts

and provides comfort and safety to the residents.

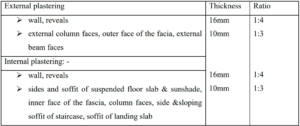

The mix ratio of mortar in the case of cement plastering depends on the nature of the area to be plastered. 10mm, 16mm thickness and 1:3, 1:4 cement, sand ratio is maintained.

The tools which were used for plastering at our site are the following:

- Trowels

- Floats

- Plumb-bob,

- Brush

- spirit level

- Level board

- Try square

- Measuring tap

Scaffolding was erected using GI pipes and timber to do plastering when working at the higher positions (slab, upper part of walls, floor beam side). During the plastering work being carried out the laborers wore gloves to protect themselves from skin allergies and accidents.

Before plastering is done, concrete is ground by using a grinder machine in a particular area where slab concrete is poured to a high thickness rather than the designed or required thickness. It might be caused by the movement of the formwork during the concreting placement. By doing this remedy action the defect on the surface was concealed and a smooth surface was obtained after the plastering work.

Curing is done after the completion of plastering work to increase the strength and stability of the area that should be plastered.

In plastering the mix ratio of mortar depends on the nature of the area to be plastered. 20mm thick, 1:3 cement and sand plastering is done up to DPC level. Reveals should not exceed 150mm.

There were two types of plastering used at our site.

- Internal plastering: A smooth finish is needed to give comfort to residents.

- External plastering: – Semi-roughness was maintained to protect the external surface

from weather effects.

The tools used for plastering work

Trowels

It’s used for spreading mortar, forming joints, and cutting bricks. The blade of the trowel is made of steel. Therefore it’s essential to protect it from rust. It is smooth, uncoated, flat, and flexible. The trowel should be thoroughly cleaned every time after the usage, and then it’s dried after washing and kept in a dry place.

Floats

Floats’ contribution is essential in plastering work. It’s made of wood, plastic, and steel. But wood floats are widely used. If the wood floats warp then they can’t use further works. The underside of the floats should always be smooth. After the use, it’s cleaned properly.

Measuring tapes

It’s an important & basic tool. It’s made of steel and clothes. The measurements can be read easily.

Try square

It’s used for setting right angles and bends and marking cement-sand blocks for cutting. It’s made of wood or metal.

Spirit level

It’s mostly used to check the co-level and also the formwork level. When the spirit level is laid on a flat surface, the bubbles appear between the 2 lines. And then turn it through 180º it appears again at the same place. So it can be confirmed as a horizontal surface.

Plump-bob

It’s used to maintain or check the verticality of the formwork & the plastered surface and is also used in block masonry. The plumb line of a plumb-bob is hanging at the rest points precisely to the center of the earth. It makes it possible to check the vertical accuracy of the perpendicular edges.